Handling

of Filters and Particle Traps in Correlative Microscopy

JOMESA is

manufacturer of

SEM Filter mounts and SEM particle traps.

|

|

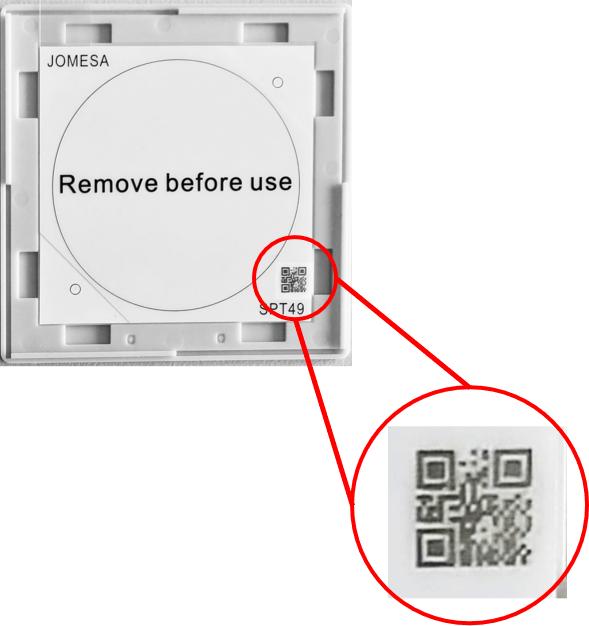

JOMESA SEM Filter

mounts: |

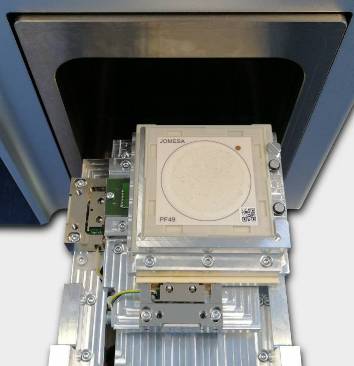

JOMESA SEM Particle

traps: |

|

|

Investigation of filters

without fixation solution is possible only in low vacuum

condition. However the risk of loosing particles by charging

effects is usually not acceptable. Even

in low vacuum fixation is recommended. |

Analysis of particle traps is possible only in low vacuum. |

Specific designed

filter/trap holders allow direct SEM-EDX analysis: |

4 Stage PSE |

|

|