The

Automatic Filter Analysis System of JOMESA:

Cleanliness

Analysis, Measurement

Process, The

patented Metal-Nonmetal recognition,

Evaluation

Samples, Oil

Cleanliness

|

JOMESA MAT3: Oil Cleanliness Analysis |

|

|

|

It

is widely known, that the cleanliness of modern oils for

automatic transmission units and high power engines cannot be

measured by optical extinction counters. |

|

|

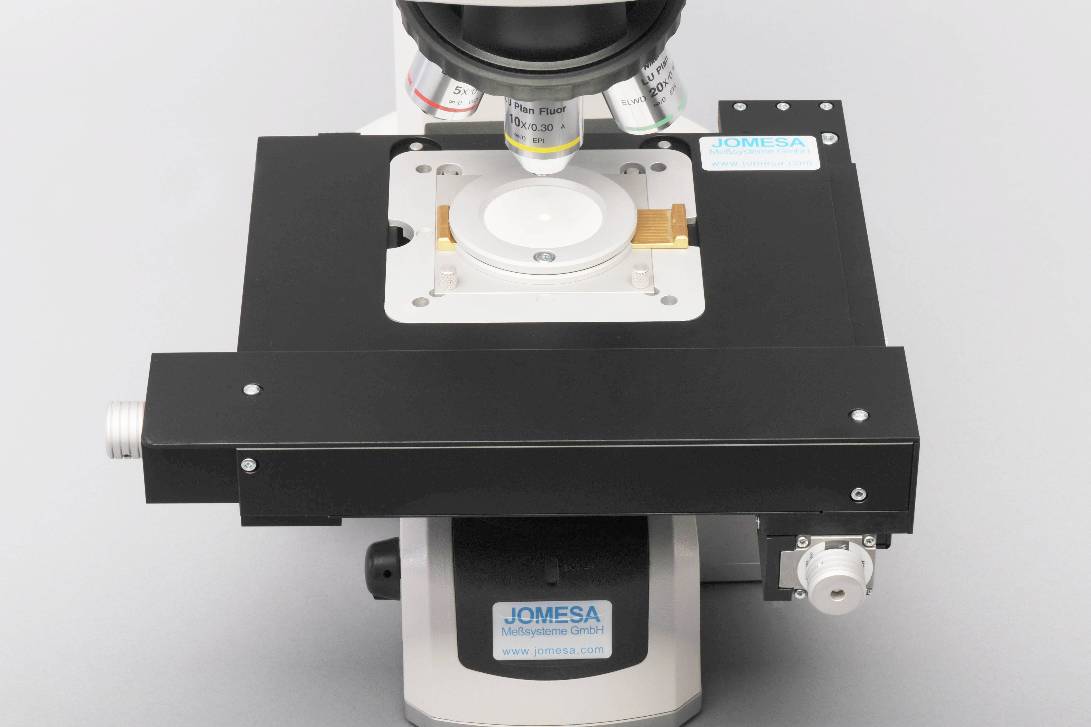

This

evolving DIN 51455 standard prescribe many operational and

equipment prerequisites, which allow to get comparable results

from different labs and operators. The

JOMESA MAT3 system based on a material microscope fully conforms

with these requirements. Automatic

height focusing (Software Autofocus) Drum

stretch filter holder Automated

light control (USB interface) with histogram based brightness

control. Particle

standard according DIN 51455 |